how does xrf measure thickness|how to interpret xrf spectra : exporter exporters exporting Premium Handheld instruments with color touchscreen for nondestructive coating . WEB25 de out. de 2023 · Tudo sobre Gabriella Saraivah. Cinema Notícias pop. Por Gabriela Giordani Última atualização 25 out, 2023 0. Na semana passada, a Prime Video lançou .

{plog:ftitle_list}

WEB19 de dez. de 2023 · Onde achar os livros do lera? Na Amazon.com.br.. Como faço para ganhar moedas no lera? Ao jogar o total de 15 partidas. você irá receber 50 moedas, se jogar 30. você irá receber 100 moedas e ao completar a. 50 você receberá o total de. Como funciona a assinatura do lera? As assinaturas renovam automaticamente a cada .

xrf thickness measurement principle

The energy dispersive X-ray fluorescence spectroscopy (XRF) is a method for measuring the thickness of coatings and for analysing materials.The analysis of trace elements places highest demands on the measuring .

comparison between rockwell and brinell hardness test

Premium Handheld instruments with color touchscreen for nondestructive coating .X-ray fluorescence (XRF) is the emission of characteristic "secondary" (or fluorescent) X-rays from a material that has been excited by being bombarded with high-energy X-rays or gamma rays. The phenomenon is widely used for elemental analysis and chemical analysis, particularly in the investigation of metals, glass, ceramics and building materials, and for research in geochemistry, Handheld X-ray fluorescence (XRF) instruments report an element-by-element analysis of a material in a wide variety of applications such as alloys, precious metals, and geological samples. However, this technology .

X-ray fluorescence spectroscopy . Then the sample is still intact after the measurement. To obtain the best accurate result, sample preparation is advised and then the XRF technique can’t be considered non-destructive. . XRF is also used to determine the thickness and composition of layers and coatings and can be easily used for rapid .Energy dispersive X-ray fluorescence (EDXRF), commonly referred to as XRF, is a fast, nondestructive method to measure the elemental composition of a material. But how does XRF work? Here, we will discuss the science behind .

from the sample, and an increase in thickness does not increase X-ray intensity. In XRF analysis, the thin film range is defined as a sample where the analyte X-ray intensity changes with thickness, and the bulk range is defined as a sample thickness where any analyte X-ray intensity does not change with thickness. In the range #1 (Fig. 1 . What is x-ray fluorescence and why is XRF sample preparation is important for correct XRF analysis. This is a little introduction to some of our instruments; from left to right we have the X-MET7000 series these hand held analyzers are great for their versatility and portability, the X-Supreme in the middle is used for bulk analysis of liquid, powder and solid .How Does XRF Analyzer Measures Coatings? An XRF coating thickness tester, as it follows from its name, emits X-rays. These rays make the inner layers shoot the atom with an electron.

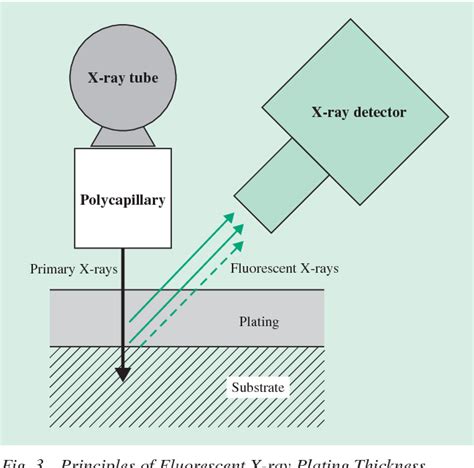

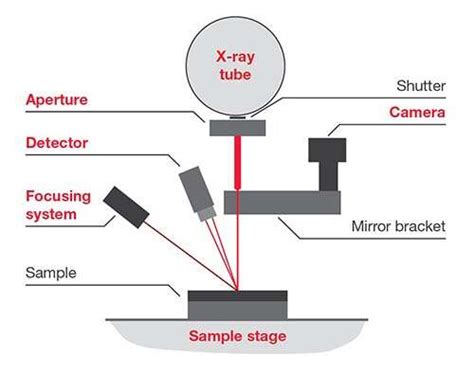

Another useful technology to measure the thickness of metal layers is X-ray fluorescence (XRF) spectrometry. The XRF method is based on the irradiation of a specimen using an X-ray tube and the measurement of the emitted X-ray characteristic from elements contained in the coating layers and the substrate.It’s important to know the limits of XRF for measuring plating thickness. The workable range of about 1nm to 50 µm is illustrated in the diagram below. Why are there limits to XRF thickness measurements? Quantitative X-ray measurements such as composition and film thickness are given by measuring the intensity of the emitted X-rays. Using different laboratory standards, an XRF can measure the thickness and composition of any metallic coating over any substrate. While the laboratory-grade XRF at Dynamix is very expensive and requires training and regular maintenance, handheld XRFs (HXRF) are becoming widely available. HXRFs operate under the same principle as laboratory .X-ray fluorescence (XRF) is a nondestructive analytical technique that allows qualitative and quantitative characterization of solids, liquids, and powders [295,296].It uses X-ray excitation to provide inorganic elemental analysis from Na up to Bk. Micro-XRF combines these properties with microscopic analysis, so that individual particles down to 10 μm and surface features can be .

Without cutting samples, measuring coating thickness on heavy or large parts is impractical, and handheld XRF can be used to overcome this limitation. The lightest, smallest and most powerful tube-based handheld XRF analyzer, the Thermo Scientific™ Niton™ XL5 Plus, measures the coat weight or coating thickness of metals accurately in seconds.X-ray fluorescence analysis is a method that uses characteristic X-rays (fluorescent X-rays) generated when X-rays irradiate a substance. . at a diameter of 3 to 6mm and thickness of 3 to 5mm, cooled by liquid nitrogen, and maintained in a vacuum. . This method involves measuring several samples of known element concentration and finding .1 Scope The purpose of this test method is to measure the thickness and phosphorous (P) concentration of chemically (electroless) deposited nickel (Ni) coatings by (energy disper-sive) X-ray fluorescence (XRF) analysis. The measurement is nondestructive and noncontact, and can be performed either in ambient atmosphere or under vacuum.X-Ray Fluorescence Spectroscopy (XRF) allows for accurate quality control of printed circuit boards and electronics, by measuring plating thickness non-destructively. It can measure the plating thickness on large and fine-pitch conductors of a variety of plating finishes: tin-lead (Sn-Pb), immersion silver (ImAg), immersion tin (ImSn .

For this analysis we use a standard substance consisting of an electroless Ni/Pd/Au multilayered plating of known thickness on a Cu substrate (infinite-thickness Cu / 5.09 µm Ni / 0.048 µm Pd / 0.051 µm Au) and use the . Information That ASTM B568 Provides While energy dispersive analyzers (ED-XRF) are more commonly used for coating measurements, the standard also covers the use of wavelength dispersive (WD-XRF) analyzers (read about wavelength vs energy dispersive XRF).The document lists the scope of the standard as covering "the use of x-ray spectrometry .X-ray fluorescence is an excellent method to not only measure plating thickness but also weight percent elemental composition of coatings. Previously, it was only possible to measure plated phosphorus content on steel substrates. New developments in XRF instrument hardware and software have extended the measurement application of

This may or may not be desirable. In effect, the hand-held XRF batch mode measures a group of parts and gives the average thickness on the entire part. The point location measurement of the benchtop XRF gives the specific thickness and/or composition value at a specific location on the part.Benchtop Energy-Dispersive X-Ray Fluorescence (EDXRF) spectrometers are compact in size and have a relatively simple setup. . The need for sample preparation is minimal and – like all XRF methods, the sample is not damaged in the process of measuring. This makes micro-XRF an ideal pre-screening technique, not only in forensics. Also, in .As noted above, handheld XRF is widely accepted for measuring alloy, base metal composition. We will focus on the measurement of coating thickness and composition with handheld XRF. XRF Spectrometry as applied to Thickness & Composition Measurement: X-ray Fluorescence is an atomic spectroscopy technique where an ionizing source The rival methods of thickness measurement, such as cross-sectioning parts and SEM analysis, are destructive; XRF is not only non-destructive, but sample prep is simple, and testing can be accomplished by operators at all skill levels. That said, there are challenges inherent in optimizing thickness measurement for conversion coatings.

To measure thickness and/or composition for a given appli-cation, it is necessary that the XRF system be calibrated using known references or standards. In calibrat- . racy of an XRF measurement refers to how close the measurement value conforms to the actual value. Mea-surement accuracy is mainly a func-XRF X-ray fluorescence analysis can be used to measure all technically relevant chemical elements. Learn more now! . Flexible measuring devices for coating thickness measurement of filigree parts like plugs, contacts or wires as well as for the determination of the metal content of electroplating baths and the composition of simple alloy .High measurement speed: Fast, simultaneous spectrum acquisition enabling short sample to sample time and the analysis of up to 700 samples per day . XRF, or X-ray fluorescence, is an analytical technique used to determine the elemental composition of materials. It is non-destructive and reliable, requires no, or very little, sample .Coating Thickness Measurement Systems From entry level to advanced XRF systems for precise small spot measurement, Bowman provides equipment and support worldwide. All XRF systems are IPC 4552-Rev. A capable. Bowman is America’s preeminent manufacturer of XRF systems and foil standards for all XRF brands and models. Call 847-781-3523

Other Thickness Measurement Techniques. There are other methods for measuring coating thickness, especially in automotive applications. These include the Coulometric, beta backscatter, and X-ray fluorescence techniques. The Coulometric method has many important functions, such as measuring duplex nickel coatings in automotive applications.

xrf plating thickness measurement

xrf machine for plating thickness

compass test harder than act

xrf coating thickness measurement

Turismo - Hotel Fazenda São Matheus

how does xrf measure thickness|how to interpret xrf spectra